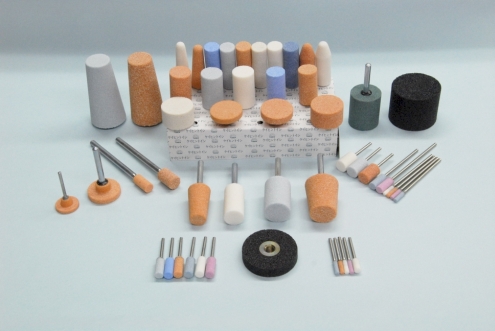

Mounted Wheels and Screw-on Wheels

Superfinishing stones are usually vitrified bond grindstones which are frequently used in superfinishing of auto parts, consumer electronics and other precision machine parts, which require high accuracy and ultraprecision.

Enquiry Now

Standard Selection of Mounted Wheels

1) Selection of Abrasive Grain

| Work Material Surface Roughness |

Hard Chrome Plated | Standard Cast Iron | Stainless Steel | Steel (HRC60) |

|---|---|---|---|---|

| Rough Finish (0.9-0.7micro) |

WA600RH20 GC600RH30 |

WA600RH20(+S) GC600RH30(+S) |

WA600RH10(+S) GC1000RH30(+S) |

WA600RH10(+S) GC1000RH30(+S) |

| Medium Finish (0.6-0.4micro) |

WA1000RH30(+S) GC800RH50 |

WA1200RH60 GC1000RH70 |

WA1000RH50 GC1500RH60 |

GC1500RH60 |

| Super Finish (0.3micro or less) |

WA2000RH20 GC1500RH60 |

WA2000RH50 GC2000RH60 |

WA1500RH40 GC2000RH60 |

GC2000RH40 |

2) Grain Size

Grain size is determined by factors such as the purpose of grinding, the work condition and shape/dimension of the wheel. Generally, grain sizes within the range of F46-F180 are used.

3) Grade

Generally, harder grade (grade L-Q) wheels are used because of the grinding condition and other constraints (such as operating speed, wheel shape and tools used).

4) Structure

Wheels of comparatively dense, high in grain ratio (structure No.8 and lower numbers) are usually used.

5) Bond

Vitrified (V) bonded wheels are most commonly used. However, impact resistant wheels such as resinoid (B), rubber (R), and urethane (UP) bonded wheels are also used.