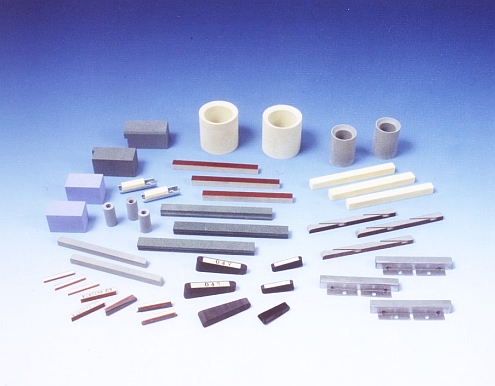

Honing Stones

Honing stones are used for accurate and efficient honing of inner surfaces of holes.

Enquiry Now

Recommendation of Honing Stones

| Work material Surface Roughness |

Steel C less than 0.3% | Steel C more than 0.3% | Alloy Steel | Stainless Steel |

|---|---|---|---|---|

| 3.0-6.0S | WA150-180RH70(+S) QB180-220H(+S) |

WA150-180RH60(+S) QB180-220J(+S) |

WA or MA80-150RH30(+S) QB180-220H(+S) |

WA180RH40(+S) QB180-220I(+S) |

| 1.5-3.0S | WA220RH60(+S) QB220J(+S) |

WA220RH50(+S) QB220J(+S) |

WA220RH30(+S) QB220I(+S) |

WA220RH30(+S) QB220I(+S) |

| 0.8-1.5S | WA320RH50(+S) | WA280-320RH40(+S) | GC280-320RH30(+S) | GC280 RH2GC120M UP |

| 0.2-0.8S | WA800 RH90 GC320RH70 |

GC600 RH90 GC320RH60 |

GC600 RH30 | GC600 RH10 GC120UP |

| Standard Cast Iron | Special Cast Iron | Aluminum Alloy | Honing Allowance | |

| GC120-180RH80(+S) QB180-220K(+S) |

GC120-150RH60(+S) QB180-220J(+S) |

GC80M UP | 0.10-0.50 | |

| GC220RH70(+S) QB220H(+S) |

GC220RH50(+S) QB220J(+S) |

GC120M UP | 0.05-0.10 | |

| GC320RH60 | GC320RH40 | GC220M UP | 0.01-0.05 | |

| GC800 RH40 GC320RH70 |

GC800 RH30 GC320RH60 |

GC320M UP | 0.01 or less | |

At a honing work, roughness of the surface finish differs greatly depending upon the honing machine and work condition. On selecting a honing stone, please inform of following items and consult thoroughly about the selection.

1. Workpiece

- Material

- Heat Treatment

- Shape and Dimension

- Honing Allowance

- Surface Roughness Requirement

- Crosshatch angle

2. Honing Machine

- Name of the machine

- Honing Oil

3. Working Conditions

- Rotation Speed (Operating Speed)

- Stroke Speed

- Grinding Pressure

- Work Timing