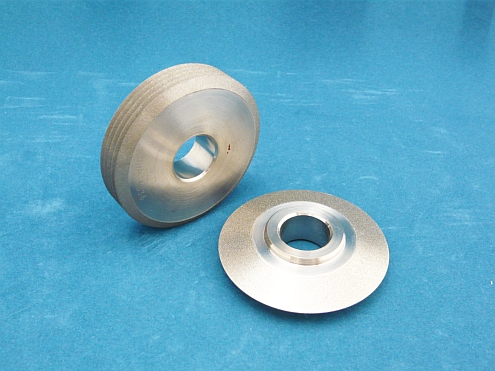

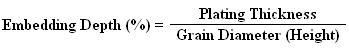

Electroplated Tools

Electroplated tools are produced by fixing grain with single layer nickel plating. With the excellent grain protrusion, they have excellent cutting ability and removal speed. Since grains are fixed by plating method, forming wheels of complicated shape can be produced comparatively easily, given the steel core can be made.

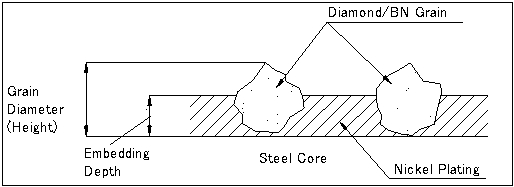

Although the embedding depth of grains should be determined depending on the grinding condition, generally 60%, and for heavy grinding and corner grinding 70% should be adequate.

Enquiry Now

Electroplating Standard (Diamond/CBN)

| Grain Size Indication | Grains Used | Grain Diameter (Height) mm |

|---|---|---|

| 30 | 30/40 | 0.9 |

| 40 | 40/50 | 0.6 |

| 50 | 50/60 | 0.45 |

| 60 | 60/80 | 0.325 |

| 80 | 80/100 | 0.25 |

| 100 | 100/120 | 0.2 |

| 120 | 120/140 | 0.175 |

| 140 | 140/170 | 0.15 |

| 170 | 170/200 | 0.14 |

| 200 | 200/230 | 0.125 |

| 230 | 230/270 | 0.105 |

| 270 | 270/325 | 0.09 |

| 325 | 325/400 | 0.075 |

| 500 | MC40/60 | 0.06 |

| 600 | MC20/40 | 0.05 |

| 800 | MC20/30 | 0.035 |

| 1000 | MC15/20 | 0.025 |

Embedding Depth

| Kind of Wheel | Embedding Depth (%) |

|---|---|

| Cutter | 60-70 |

| Wheel | 55-60 |

| File | 70 |

| Hole Saw | 70 |

| Internal | 50-60 |

| Other | depends on condition |

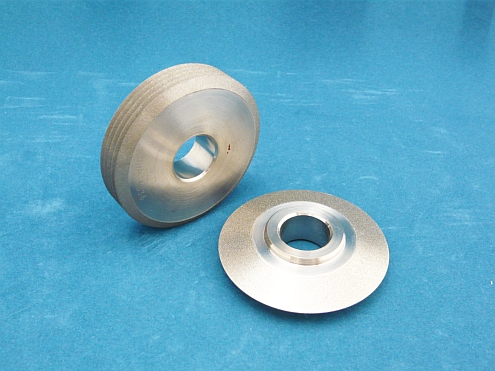

Double-Layer Plates

Double-layer plates are made by fixing second layer grains with nickel plating after fixing grains with a single layer nickel plating. The first layer maintains cutting ability while the second layer, which is preserved strongly, shows extraordinary long-life in work including heavy grinding and boring of non-ferrous such as glass.

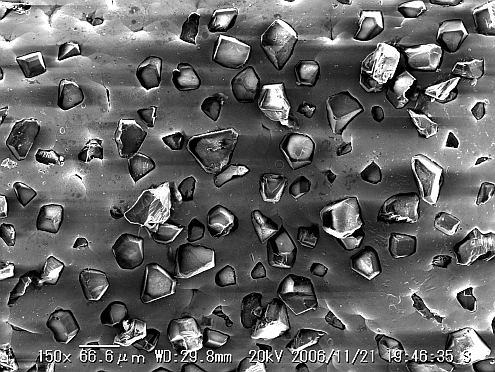

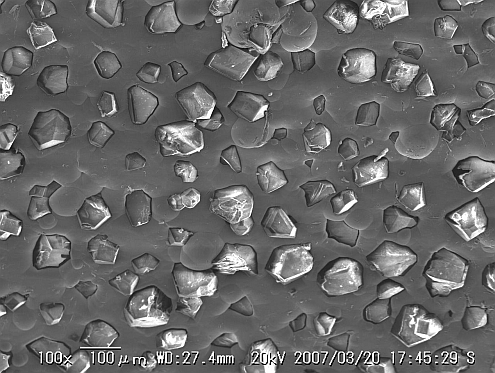

*Double-layer Plate

The picture shows the base abrasive layer underneath the second layer.