Diamond/CBN Honing

Honing Process

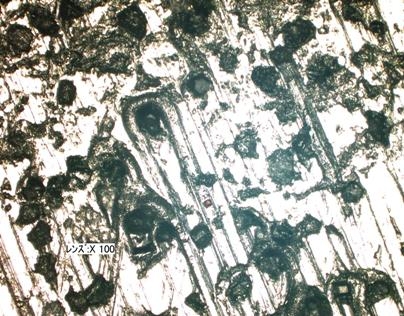

Honing is the process of finishing inner surface of precision machine parts to a high degree of accuracy and smoothness by a combination of rotary and reciprocating motions with appropriate pressure.

Enquiry Now

Functions and Merits

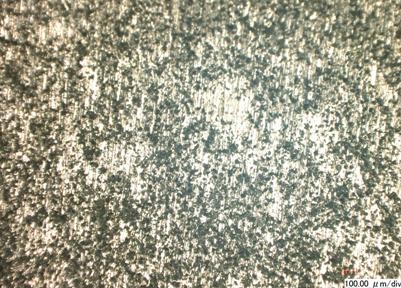

Combinations of rotation speed and stroke speed form variety of crosshatch grinding tracks on the surface of a workpiece.

These crosshatch tracks help holding oil and improve wear resistance of the product.

– Since honing stones contact with workpiece at wide area, force that affect each grain is small, which results in excellent finished surface with small surface roughness and less affected layer.

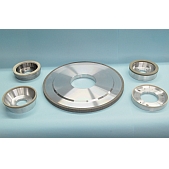

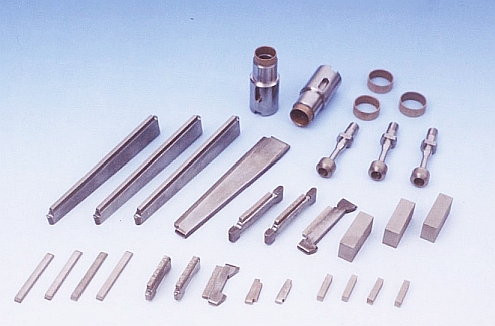

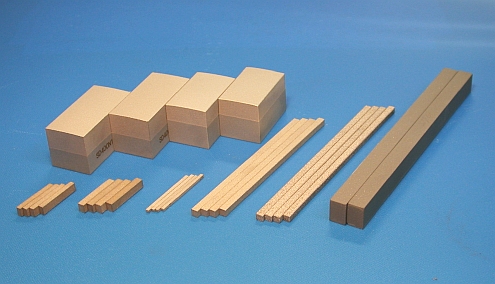

Features of Diamond/CBN Honing Stones

With ordinary vitrified grindstones, it was hard to fully meet users’ requirement because they were short life, easily caused partial wear and deformation and could not maintain machining accuracy. However, by using CBN/Diamond grains, work can be done easily even with workpieces which were difficult to process, while maintaining long life.

In most cases, metal bond is used for an Diamond/CBN honing stone. By combining several metals, and varying selection of grain, grain size and concentration, a honing stone can be produced to suit any kind of workpiece.

Features of Keihin Honing Stones

Keihin honing stones are produced to maximize the productivity of super abrasive grains. With their high efficiency, long-life and high accuracy, Keihin honing stones largely contribute to reduction of cost and boosting productivity of many companies.

Problems with Honing

Fixed exchange truck

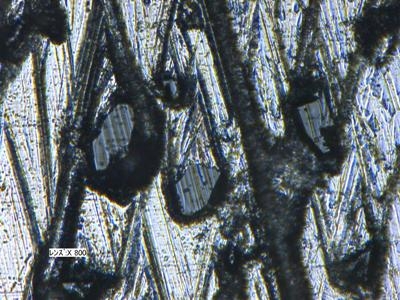

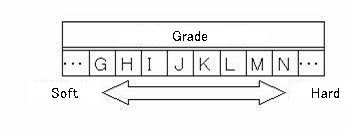

1. Dulling

– Cutting ability declines with grain wear and increased friction.

– [Counter-plan] Select grain with high crushability and soft bond to expedite selfgeneration of cutting edge.

2.Clogging

– Chips get into pores of the stone surface.

– [Counter-plan]Select softer bond. Adjust concentration.

3.Premature Grain Loss

– Grains drop off without wear, almost in original shape.

– [Counter-plan]Select harder bond to hold grains well.

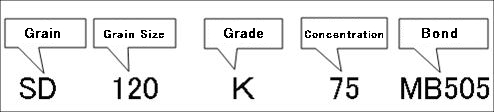

Indication of Diamond/CBN Honing Stones

Indication of Specification

Selection of Grain

Diamond and CBN are available to be selected depending on the material of workpiece

Diamond: diamond

CBN: boron nitride

Selection of Grain Size

Determined by the required surface roughness i#40-#6000j

Grade and Bond

Grade consists of both hardness (wear resistance) of metal material and binding condition with grains, so that more suitable selection can be made.

We prepare bond other than stated above as necessary to suit every honing condition.

Concentration

Concentration indicates grain weight per cm3 and is usually justified in steps of 5% between 20% and 150%.

At honing work, surface finish differs greatly depending upon the honing machine and work condition. On selecting a honing stone, please inform our service person of following items and consult thoroughly about the selection.

Work Condition Material

- Honing Length

- Heat Treatment

- Work Pressure

- Honing Inside Diameter

- Cycle Time

- Honing Allowance

- Name of the Machine

- Surface Finish Requirement

- Honing Oil Manufacturer

- Machining Accuracy

- (Water-soluble or Oil-based)

- Crosshatch Angle

- Spindle Speed

- Stroke Speed