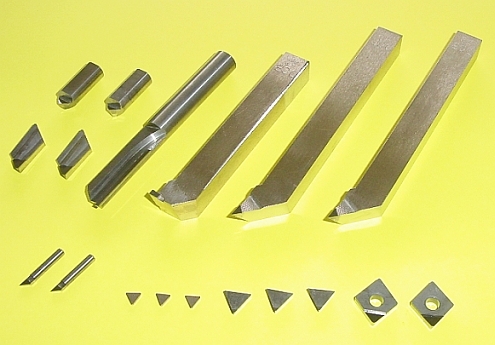

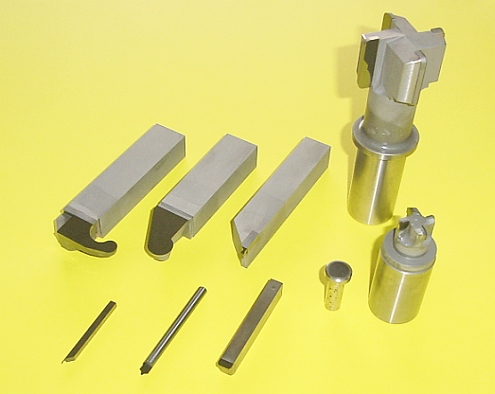

Diamond/CBN Compact Tools

A diamond/CBN compact is a sintered compact of diamond (CBN) grains and cemented carbide with metal catalyst such as cobalt. It has the characteristic of diamond such as hardness, wear resistance and heat conductivity as well as toughness of cemented carbide. Since cobalt as metal catalyst allows electrical discharge machining, a diamond/CBN compact can easily be made into various shapes. Therefore, diamond/CBN compacts are used as parts of wear resistant tools including cutting edges of cutting tools such as single-point tools, rest shoes and lower shoes.

Enquiry Now

Application of Diamond Compacts

Application of diamond compact is limited to work condition where cutting temperature does not exceed 700 Celsius, and workpiece material should not have affinity to carbon. A diamond compact can be used for non-ferrous metal, precious metal and their alloys (such as aluminium, copper, silver, magnesium) and also can be used as wear resistant parts including machine chatter suppression, guide, supporting tool and measuring devices.

Application of CBN Compacts

CBN compact, with its stability at the temperature up to 1200 Celsius and chemically inert characteristic, can resist high temperature in machining of steel metal. Thus, CBN compact can be used for cutting of hard steel materials (45-65HRC) including quenched steel, nickel and chromium-iron alloy.