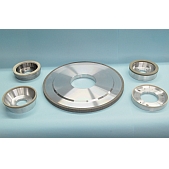

About CBN Wheels

Features of CBN Wheels

Super grain CBN (cubic boron nitride), developed by General Electronic in the United States, is the hardest grain next to diamond and is highly stable under heat. It is suitable for the field including tool steel, die steel and cast iron higher than HRC50, and nickel/cobalt base superalloy higher than HRC40.

Compared to general alumina wheels, CBN wheels are excellent in removal efficiency, long-life, easy to control dimension of workpiece, highly durable, generates less grinding heat and hardly causes burn. Thus, they can be used for continuous production for a long time.

Enquiry Now

Rotation Speed of Wheel

Since CBN grains have excellent stability under heat, the higher the rotation speed gets, the higher the grinding ratio becomes, as long as the rigidity of the grinding machine permits.

Refer to the following table to avoid workpiece burn, especially in dry grinding.

| Wet Grinding | 28m/s-60m/s |

|---|---|

| Dry Grinding | 17m/s-23m/s |

Grinding Fluid

Since CBN grain may be decomposed into ammonia and boric acid when it reaches at the temperature of 900 Celsius under water vapor atmosphere, avoid using grinding fluid which contains fresh water or anticorrosive. You can get good result by using 5% of water-soluble oil designed for light grinding.

For higher grinding ability and longer wheel life, use 5-10% of water-soluble oil designed for heavy grinding.

Sulfur mineral oil with additives such as sulfur and chlorine reduces grinding friction and improves the life of wheel.

Truing and Dressing

Truing may be applied in various method including with brake dresser, with stick, by mild steel grinding and with impregnated dresser. In any case, always do it by wet grinding and make sure there is enough grinding fluid at the contact point of wheel and truing tool.

Use A (Alundum/Alumina grain) vitrified stick for dressing to unload a wheel and expose the cutting edges.

The grain size of a stick should be one or two rank(s) finer than that of a CBN wheel. Also, the grade should be within E-H. For effective dressing, push stick tightly to the wheel and adjust the amount of grinding fluid so that slurry appears on the surface of the wheel.

Selection Guideline of CBN Wheels

The criterion of selection of the grain size when replacing an alumina wheel with a CBN wheel is as shown in the table below.

| Alumina Wheel | CBN Wheel |

|---|---|

| F46-F60 | F80-F120 |

| F80-F120 | F140-#270 |

| #270- | #325-#400 |