QB Grinding Wheels

Amazing Super Ceramics

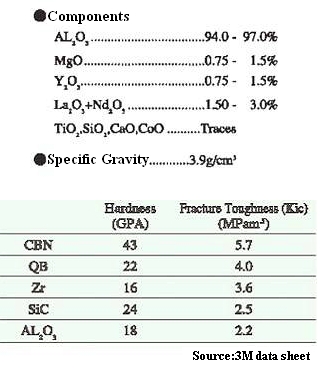

A QB grinding wheel, which is developed with the new ceramic technology, has excellent grinding characteristics compared to ordinary alumina wheels. (3M Cubitron 321)

A QB grain is a high purity alumina wheel. It not only has the characteristics of ordinary grains, but also has a unique crystal structure.

The uniqueness of the crystal structure of QB permits excellent grinding results that ordinary grain can never reach.

Enquiry Now

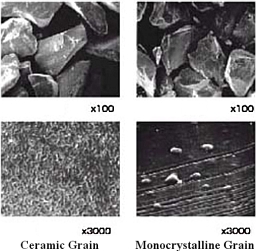

SEM Graph of QB Grain

As you can see in the graphs on the following, the crystal structure of QB grain has a unique structure of very fine grains sintered together. As a grinding work progresses, this sintered fine grains structure causes microfracture and sharp cutting edges successively selfgenerate against the workpiece.

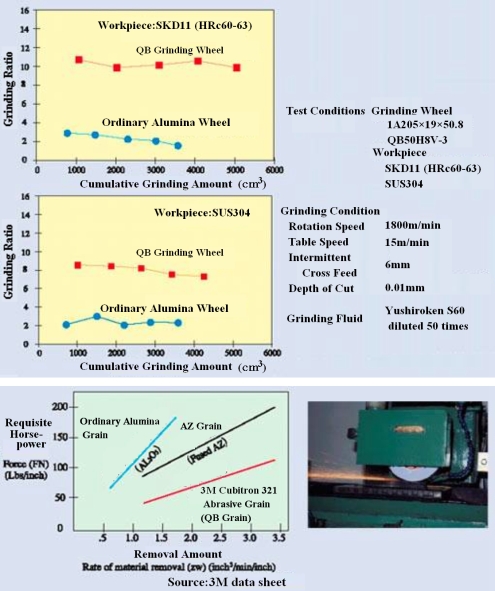

Thus, QB grinding wheels produce minimal friction and even if operated under heavy duty grinding conditions, can maintain stable cutting ability.

Characteristics of Ceramic Grain

Grinding Data of QB Grinding Wheels

Features of QB Grinding Wheels

QB grinding wheels are produced in a method slightly different from that of ordinary vitrified grinding wheels. QB grinding wheels are produced with the special bond and the scientific firing method that conform with Ceramic grains.A QB grinding wheel can be used just in the way you use on a grinding machine.

1. Sharp cutting edges at all times!

The unique sintered structure of Ceramic Grain, which is the structure of very fine grains sintered together, causes microfracture and sharp cutting edges successively selfgenerate on the surface of a grinding wheel. The sharp cutting edges permit quiet and productive grinding.

2. Minimal deformation!

Grinding friction is very small thanks to the numerous sharp cutting edges. This results in high preservation of wheel form and economical grinding.

3. Reduce dressing amount and frequency!

The selfgenerating fine cutting edges maintain productive grinding even under reduced amount and frequency of dressing. This reduces wheel wear and results in economical grinding.

4. Wide range of application!

With sharp cutting edges at all times, productive grinding in wide range of application can be achieved with the same grinding wheel. The need of switching grinding wheels depending on workpiece conditions such as kind, tempered/non-tempered and so on will be reduced.